WET SCRUBBERS

1. A device manufacturer discovered significant build up of explosive deposits downstream of their photoresist strip tools. Airgard scrubbers were installed to remove the explosive ammonium compounds  from the gas stream before they can plate out in the exhaust plumbing.

from the gas stream before they can plate out in the exhaust plumbing.

2. In 2004 a silicon wafer manufacturer contacted Airgard with a request to help reduce the down time they were experiencing in their epi fab. It was soon found that with their fab’s 27 epitaxial reactor chambers running at full production rates, the existing abatement system was requiring approximately 370 hours a year of down time in scheduled preventative maintenance alone. As a result of the high maintenance, unreliability and the inefficiency of their existing scrubber abatement system, the company estimated that they were unable to process over 12,000 wafers at a cost of approximately $890,000 per year in lost revenue. Airgard Cyclone scrubbers were installed to replace their existing abatement system and the cost savings became immediately apparent. The AIRGARD scrubbers wasted less gasses, water and power and also reduced yield losses, resulting in a conservative ROI of just 13 months. The customer operated these scrubbers in their fab for 6 years, saving them over $4 million. They have since moved the Airgard scrubbers to another line where they continue to operate and save money for the company.

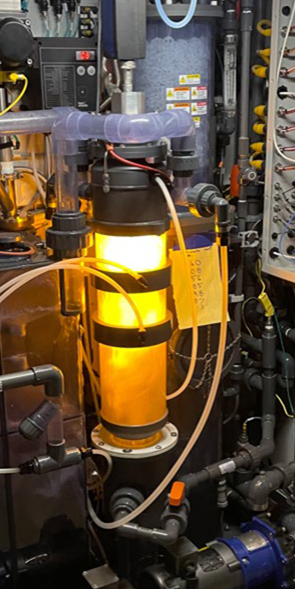

WET-BURN-WET SCRUBBERS

1. A Top Ten Semiconductor company evaluated a new option in exhaust management from Airgard on a silicon nitride CVD process. Airgard Encompass -the world’s first Wet-Burn-Wet abatement tool integrating wet scrubbers prior to a methane burner and followed by a wet scrubber - was compared to a legacy Burn-Wet abatement tool. Encompass eliminates water soluble and water reactive gases prior to thermal decomposition virtually eliminating NOx emissions for processes using NH3 (ammonia) as well as significantly extending the maintenance cycle while preserving linear abatement performance for Green House Gas destruction.

prior to a methane burner and followed by a wet scrubber - was compared to a legacy Burn-Wet abatement tool. Encompass eliminates water soluble and water reactive gases prior to thermal decomposition virtually eliminating NOx emissions for processes using NH3 (ammonia) as well as significantly extending the maintenance cycle while preserving linear abatement performance for Green House Gas destruction.

2. Procedures were consistent with the EPA Protocol for Measuring Destruction or Removal Efficiency of Fluorinated Greenhouse Gas Abatement Equipment in Electronics Manufacturing (EPA 430-R-10-003) March 2010. Incoming concentrations of NH3 were similar but output concentrations were not with N2O readings from Encompass Below Detectable Limits and overall NOx emissions reduced by over 90%. After testing the Encompass ran without maintenance for over 13 months and the customer calculated cost savings of 60% lower than the previous Tool Of Record (TOR).

For more information: 408.573.0701 or email orders@airgard.net